Our YT360 is a top-of-the-line Hydraulic Dth Drilling Rig. It’s made for tough blasting jobs in mines, quarries, and big excavation projects. It handles hard rock well. And it keeps working efficiently—with little downtime.

This is professional Drilling Equipment For Excavation. It has a strong hydraulic system and a tough frame. Great for teams that need reliable performance, day in and day out. Whether you’re drilling blast holes for ore or prepping a site, the YT360 gets the job done right.

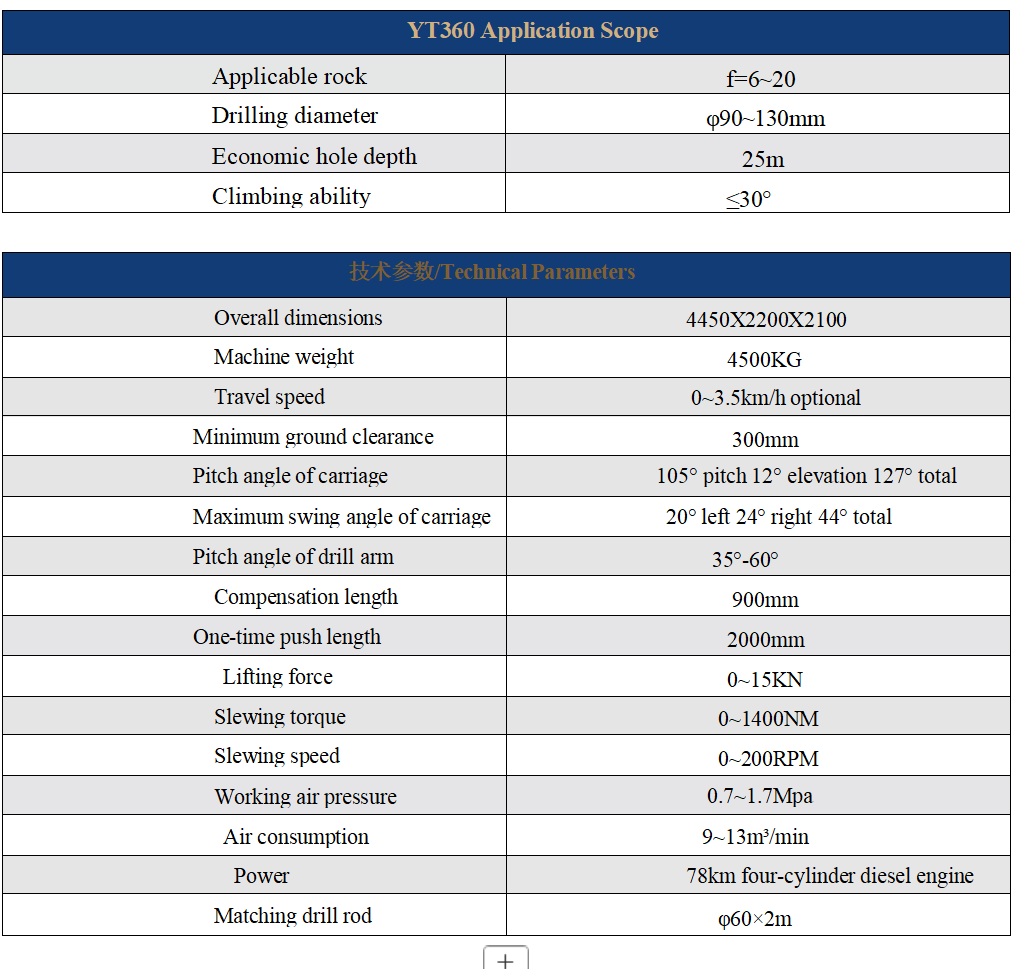

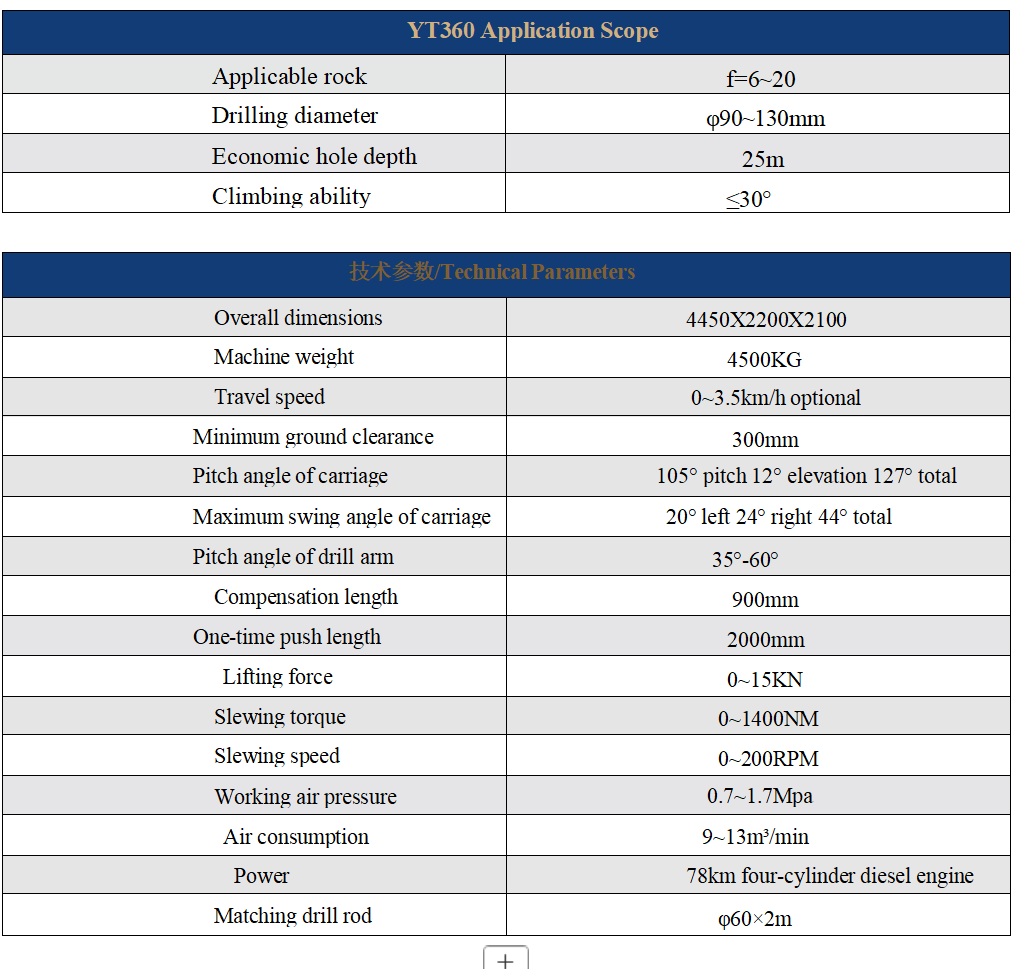

Technical Specifications

- Operating Weight: 12 tons

- Engine Power: 92 kW / 125 HP diesel engine

- Drilling Diameter: 90-250 mm

Product Images

Check out these high-res photos of the YT360 Down-the-hole Drilling Rig. You’ll see its design, parts, and how it works on actual job sites:

Product Features & Competitive Advantages

Core Features of the YT360

- High-Power Hydraulic System: This Hydraulic Dth Drilling Rig has two separate systems. One spins the drill. The other runs the hammer. Uses 18% less energy than rigs with one system. Drills steady even in hard rock.

- Rugged Steel Frame: The main body and drill mast are made of Q355 high-strength steel. It handles heavy vibration from hard rock drilling. Lasts 35% longer than lighter rigs.

- Easy Control Panel: Digital display shows real-time info—depth, speed, pressure. It’s in simple language. And it has auto-overload protection. If the drill hits something too hard, it slows down to avoid damage.

- Comfortable Operator Cabin: It’s quiet inside, with AC. The seat adjusts, and you can see all around. Controls are laid out like a car dashboard. Easy to learn—even for new operators.

- Dual Dust Suppression: Comes with both water mist and dry dust collection. You can switch between them. Cuts down 92% of airborne dust. Keeps workers healthy and meets safety rules worldwide.

Why It’s Better Than Competitors

- Faster Drilling: Drills 25% faster in granite—over 10 meters an hour. That’s faster than other 12-ton rigs. We set up the hammer and air pressure to work perfectly together.

- Uses Less Fuel: Only 35-40 liters an hour. That’s 12% less than other rigs.

- Works in Any Weather: Handles -20°C to 50°C. Add our cold-weather package (engine heater) for freezing areas. Or a hot-weather package (extra oil cooler) for deserts.

Step-by-Step Operation Guide

- Pre-Operation Check

- Check fuel, engine oil, hydraulic fluid, and coolant. Use the panel gauges—no need to open the tanks.

- Look at the drill bit. If the cutting edge is worn 4mm or more, replace it. Check for cracks too.

- Test safety tools. Press the emergency stop button—it should shut down everything. Check track brakes and lock the drill mast.

- Clear the area. Move obstacles 6 meters away. Make sure no one is in the blasting zone.

- Site Positioning & Leveling

- Drive the rig to the drilling spot using the crawler tracks. Avoid soft ground. Use steel plates if it’s muddy.

- Level the rig. Use the outriggers to adjust until the bubble level on the dash is centered.

- Line up the mast. Use the laser pointer in the cabin to aim at the marked blast hole. No guesswork needed.

- Set Drilling Parameters

- Pick the right bit. Tungsten carbide for hard rock (80+ MPa). Diamond for super-hard rock.

- Enter the depth on the panel (max 30 meters). Set speed: 40-50 rpm for hard rock, 60-75 rpm for soft rock.

- Set compressor pressure to 1.5-1.8 MPa. Keeps dust down and makes the hammer work well.

- Start Drilling

- Lower the mast slowly until the bit touches the rock. Don’t drop it—you’ll break the bit.

- Turn on rotation first, then the hammer. Keep steady pressure (1.0-1.5 kN for hard rock).

- Watch the display. If pressure goes over 250 bar or temp hits 70°C, stop drilling. Something’s wrong.

- Finish & Shutdown

- When you reach the target depth: Stop the hammer first, then rotation. Pull the bit out slowly.

- Raise the mast to transport position (under 30° tilt) and lock it.

- Clean the bit and mast with high-pressure air. Check for oil leaks—look under the rig for wet spots.

- Write down the job details: depth, time, fuel used. Helps with future maintenance.

Where It Works Best

The YT360 Down The Hole Drilling Machine is made for blasting jobs across industries. Here’s where it does its best:

- Surface Mining: Great for pre-blasting in coal, iron ore, and gold mines. Drills even holes (90-250mm) so rocks break evenly. Cuts ore loss by 10%.

- Quarrying: Used in limestone, granite, and marble quarries. Drills 30-meter holes for large block extraction. Improves block yield by 15%.

- Infrastructure: Needed for highway expansions, railway tunnels, and dam building. Preps blast holes to clear rock in mountainous areas.

- Demolition: Safe for taking down old factories, bridges, and rock formations. Precise hole placement means controlled collapse—no unexpected damage.

- Geothermal Drilling: Works for shallow geothermal wells (15-25 meters). We can add corrosion-resistant bits for salty or acidic soil.

What You’ll Gain

- Faster Projects: Drills 25% faster, so projects finish sooner. For example, a 15,000 m² quarry finishes monthly blasting 7 days earlier. That’s 20% more output each year.

- Easy to Train: Simple controls mean new operators learn in 1-2 days. No need for expensive long-term training.

- High Resale Value: Our tough build means it keeps 45% of its value after 5 years. The market average is 30%.

Certifications & Safety Compliance

Our Drilling Equipment For Excavation meets global standards. It works in projects worldwide:SGS Certified – Ran 1,200 hours straight in tough conditions with no breakdowns. Proves it’s reliable.

- OSHA 1926.602 – Meets U.S. safety rules for construction and mining drilling.

- Australian AS/NZS 4024 – Approved for use in Australian mining and quarrying projects.

Customization Options

Every job is different. We can adjust the YT360 to fit your needs. Custom rigs take 20-35 days to make.

- Drill Bits: Custom sizes (80-260mm) and materials.

- Transport Adaptations: Foldable drill mast (lowers to 2.8 meters) for countries with strict road height limits.

- Branding: Custom paint colors and logo printing. Matches your company’s fleet look.

How We Build the YT360 (And Check Quality)

We follow 6 strict steps to make sure every YT360 is top-quality. We check over 130 things along the way:

- Material Sourcing: We get Q355 steel (for the frame) and Bosch hydraulic parts from trusted suppliers. We test every batch of steel for strength. No weak materials make it through.

- Precision Cutting/Welding: CNC machines cut steel parts (error under 0.3mm). Robots weld the drill mast (99% of the weld sticks) so it doesn’t crack when vibrating.

- Component Assembly: Skilled technicians put together the engine, hydraulic system, and tracks in a clean shop. Every bolt is tightened to 60-110 N·m. No guesswork.

- System Calibration: We use professional tools (like HBM pressure sensors) to set hydraulic pressure, speed, and hammer force. Makes sure every rig works the same.

- 100-Hour Test: Every YT360 drills hard rock for 100 hours straight. We check for leaks, overheating, and that settings stay right. If it fails, we fix it until it passes.

- Final Check & Packing: We inspect the paint, parts, and paperwork (certifications, manual). Then we wrap it in waterproof material for shipping. No rust or damage in transit.

What Customers Say

"We’ve used 3 ANNENG YT360 rigs in our iron ore mine for 3 years. They drill 10 meters an hour in granite—25% faster than our old rigs. Fuel use is 38 L/hour, which saves us $12,000 a year per rig. Maintenance is easy too—we change a drill head in 45 minutes."

— David Lee, Mining Manager, Western Australia Ore Co.

"Our granite quarry in Spain needed a rig that meets EU safety rules. The YT360 has CE certification, and the dust system keeps our workers healthy. It drills 30-meter holes perfectly—our block yield went up 15%. Support is fast too—they sent a tech in 48 hours when we had a question."

— Marco Rossi, Quarry Owner, Barcelona Granite Group

"We bought 2 YT360s for our highway project in Kenya. They work great in 45°C heat—no overheating issues. The GPS upgrade helped us drill 600+ blast holes exactly where we needed them. We finished the project a month early, which made the client happy."

— John Ochieng, Construction Contractor, Nairobi Infrastructure Ltd.

Common Questions

How often does the YT360 need maintenance?

Regular checks: Every 300 hours of use. Change engine oil, hydraulic filter, and air filter. Major service: Every 1,200 hours. Check mast welds, replace hydraulic hoses, and calibrate the control panel. We include a step-by-step manual—no prior experience needed.

How long do drill bits last? Where can I buy replacements?

Bit life depends on the rock. 600-900 meters in granite. 900-1,300 meters in limestone. We sell original replacement bits. They ship to major ports in 3-7 days. We also have local distributors in 20+ countries—we’ll connect you with the nearest one.

Do you offer operator training?

Yes! We provide 2-day on-site training for your team. We cover operation, basic maintenance, and safety. After training, operators can run the rig confidently. We also offer free follow-up calls if they have questions later.

How long to get a YT360? What about shipping?

Standard rigs: 10-14 days (we have stock). Custom rigs: 20-35 days.

Does it work with other DTH hammer brands?

Yes! It fits major brands like Atlas Copco, Sandvik, and Chicago Pneumatic (3-inch to 8-inch connections). Our tech team can check if it works with your current hammers—just send us the hammer model number.

What payment terms do you accept for international orders?

We take T/T (30% upfront, 70% before shipping), L/C at sight (for orders over $150,000), and Western Union (for small orders). We also offer flexible terms for long-term clients—ask our sales team for details.